Products list

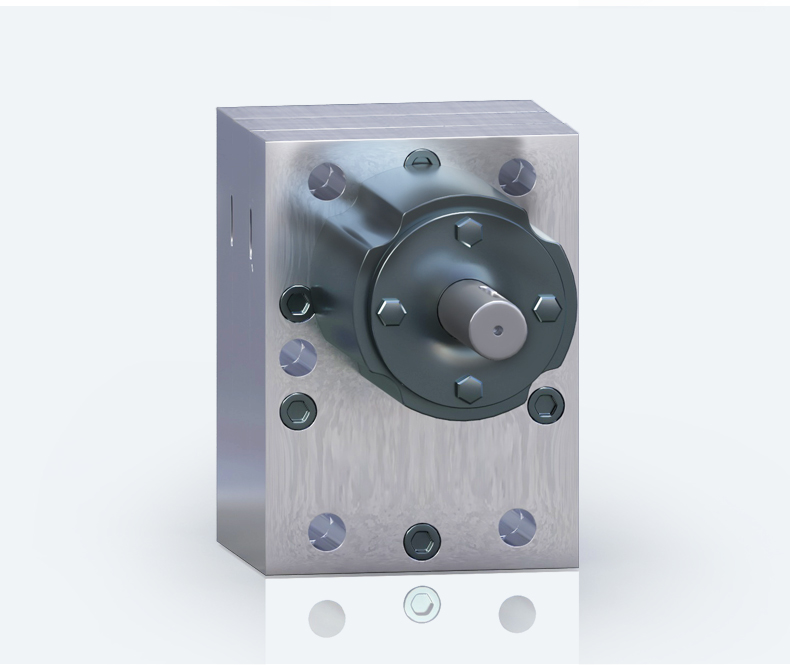

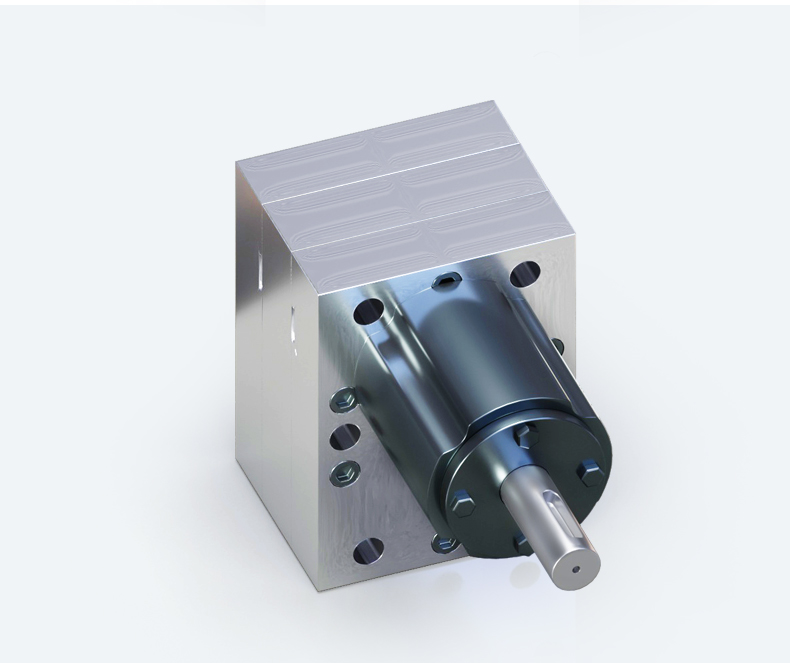

шестеренчатый насос-дозатор насос-дозатор

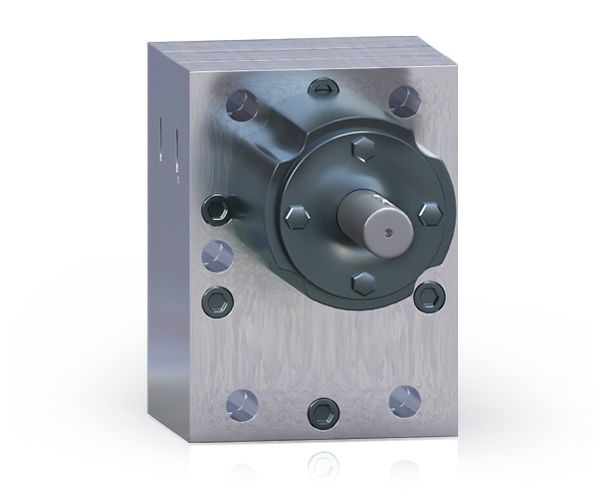

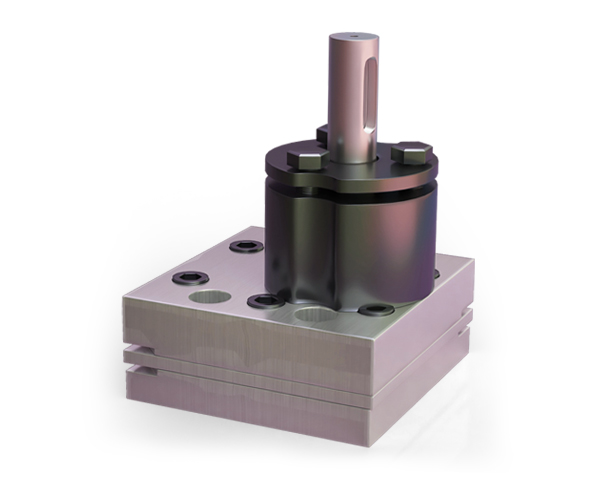

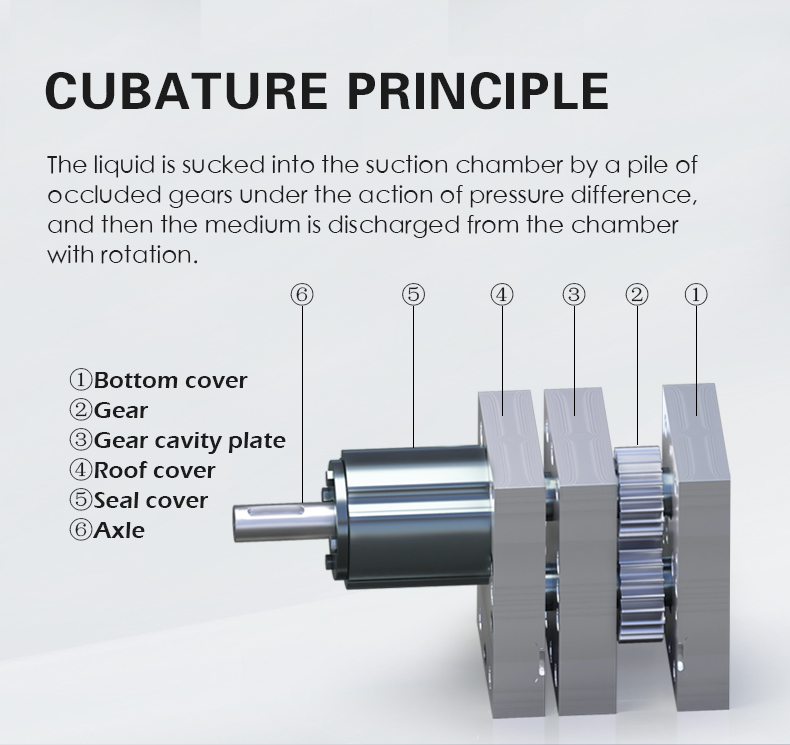

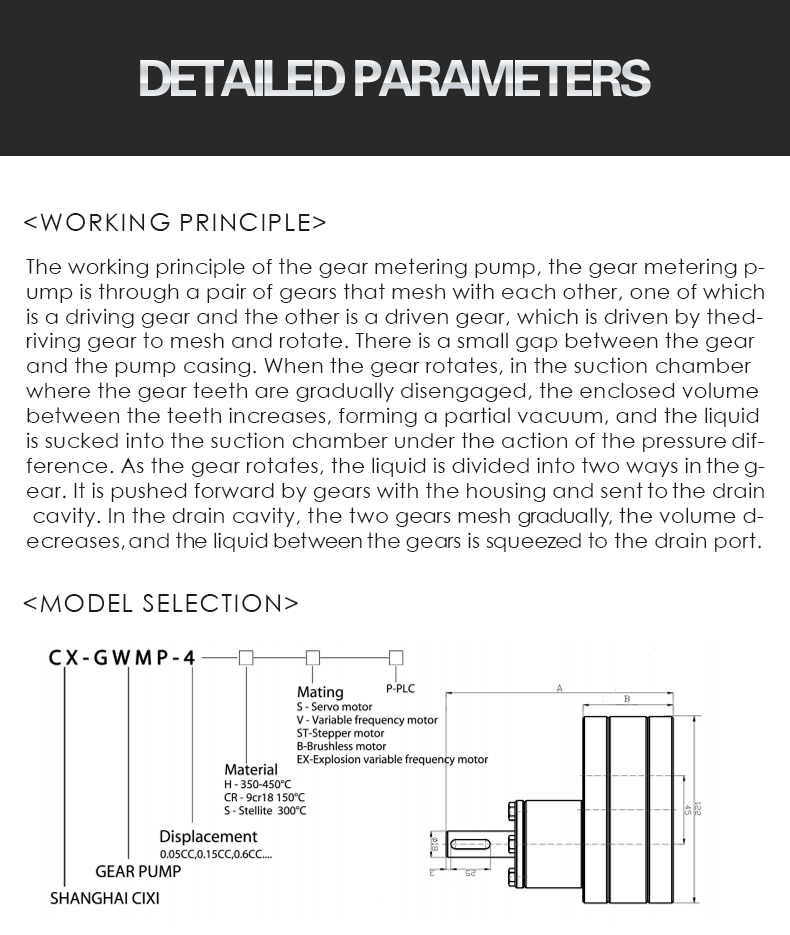

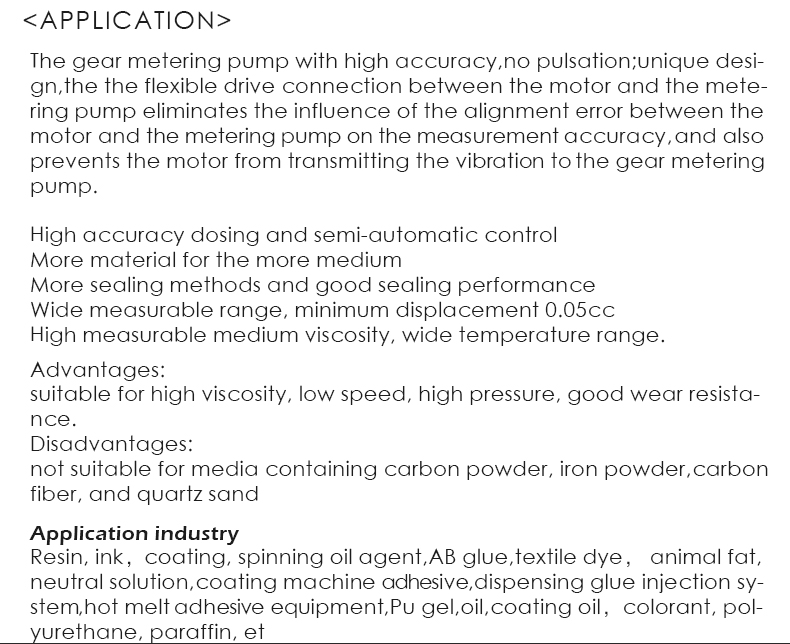

The working principle of the gear metering pump, the gear metering pump is through a pair of gears that mesh with each other, one of which is a driving gear and the other is a driven gear, which is driven by the driving gear to mesh and rotate. There is a small gap between the gear and the pump casing. When the gear rotates, in the suction chamber where the gear teeth are gradually disengaged, the enclosed volume between the teeth increases, forming a partial vacuum, and the liquid is sucked into the suction chamber under the action of the pressure difference. As the gear rotates, the liquid is divided into two ways in the gear. It is pushed forward by gears with the housing and sent to the drain cavity. In the drain cavity, the two gears mesh gradually, the volume decreases, and the liquid between the gears is squeezed to the drain port.

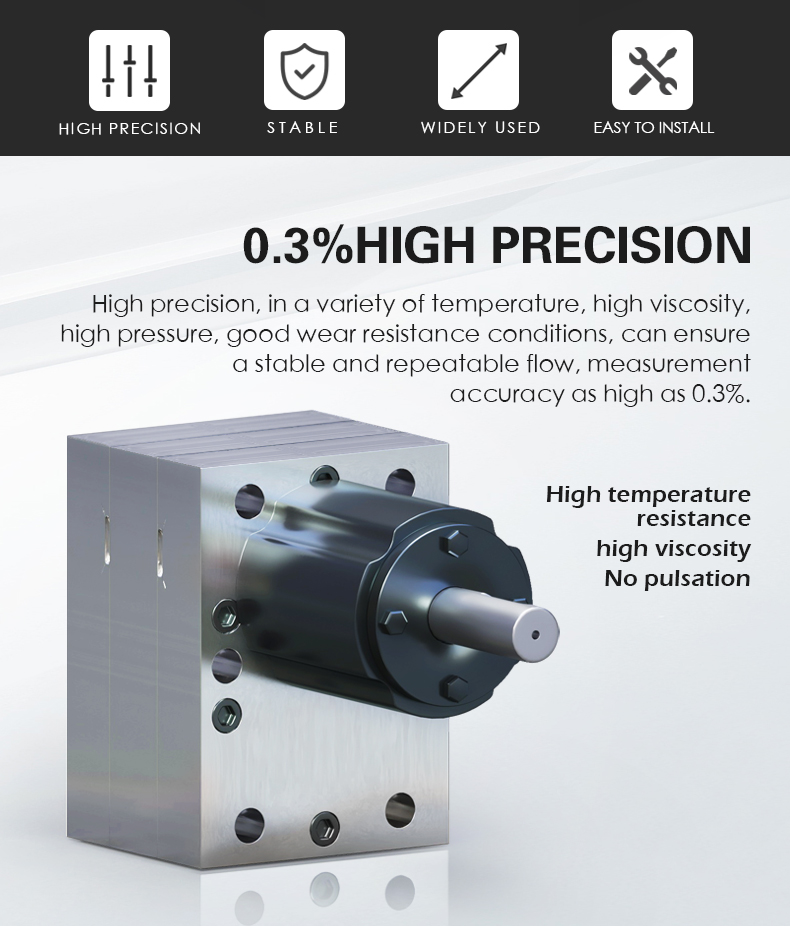

Features

| Wide measuring ranges | High viscosity | High precision |

| Low pressure drop | No pulsation | High temperatur-e resistance |

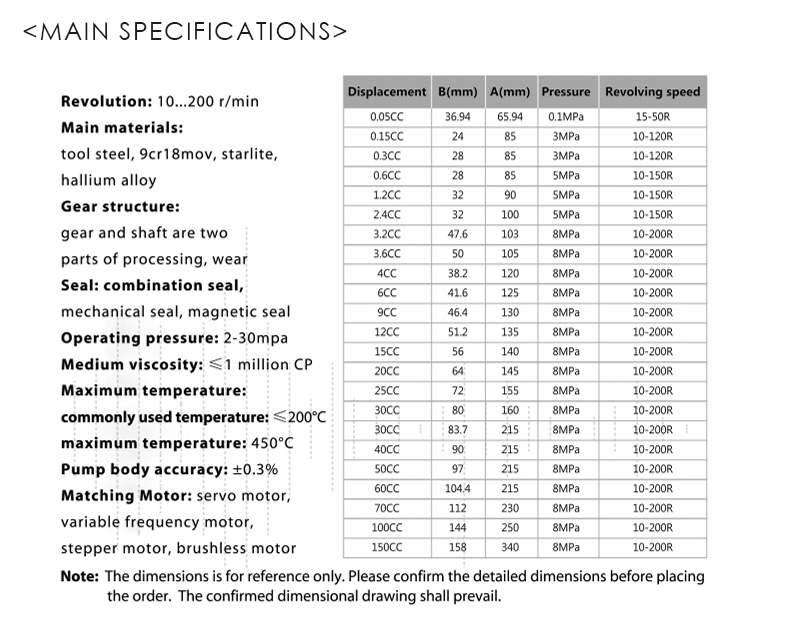

Technical Data

| Model Number: CX-GWMP | Accuracy: ±0.3% |

Working pressure: 2-30mpa | Meterial: Tool steel |

Displacement: 30~100cc | Medium viscosity: ≤1millionCP |

Revolution: 10...200 r/min | Working tempertu: ≤200℃ |

Downloads

Small displacement gear metering pump

Dateiformat P D F